Research & Development

Our mission is to provide complete, customer-specific solutions for sound, vibration, and shock problems in the North American defense market. From concept to fully engineered, manufactured systems, GLSV has a deep history of supporting both the defense and industrial markets.

Our end goal is to commercialize and manufacture products – and one of the important ways we feed this pipeline is through our numerous R&D programs. GLSV is very active in the U.S. Small Business Innovation Research/Small Business Technology Transfer (SBIR/STTR) program, especially for the US Department of Defense (DoD). We also partner with our private industry clients to undertake internal R&D efforts to explore and develop cutting edge technologies and products. Our engineers constantly strive to push the envelope with improvements to our existing products, and developing new products.

R&D Programs at GLSV:

US Navy SBIR to develop a new launch and recovery device for UUVs

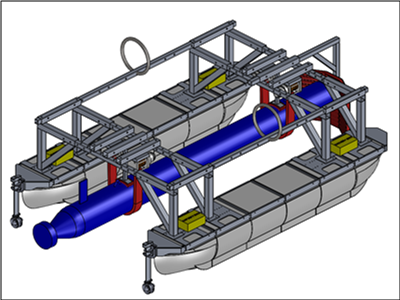

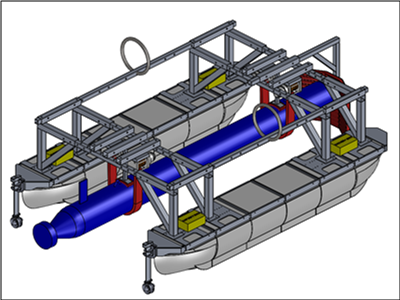

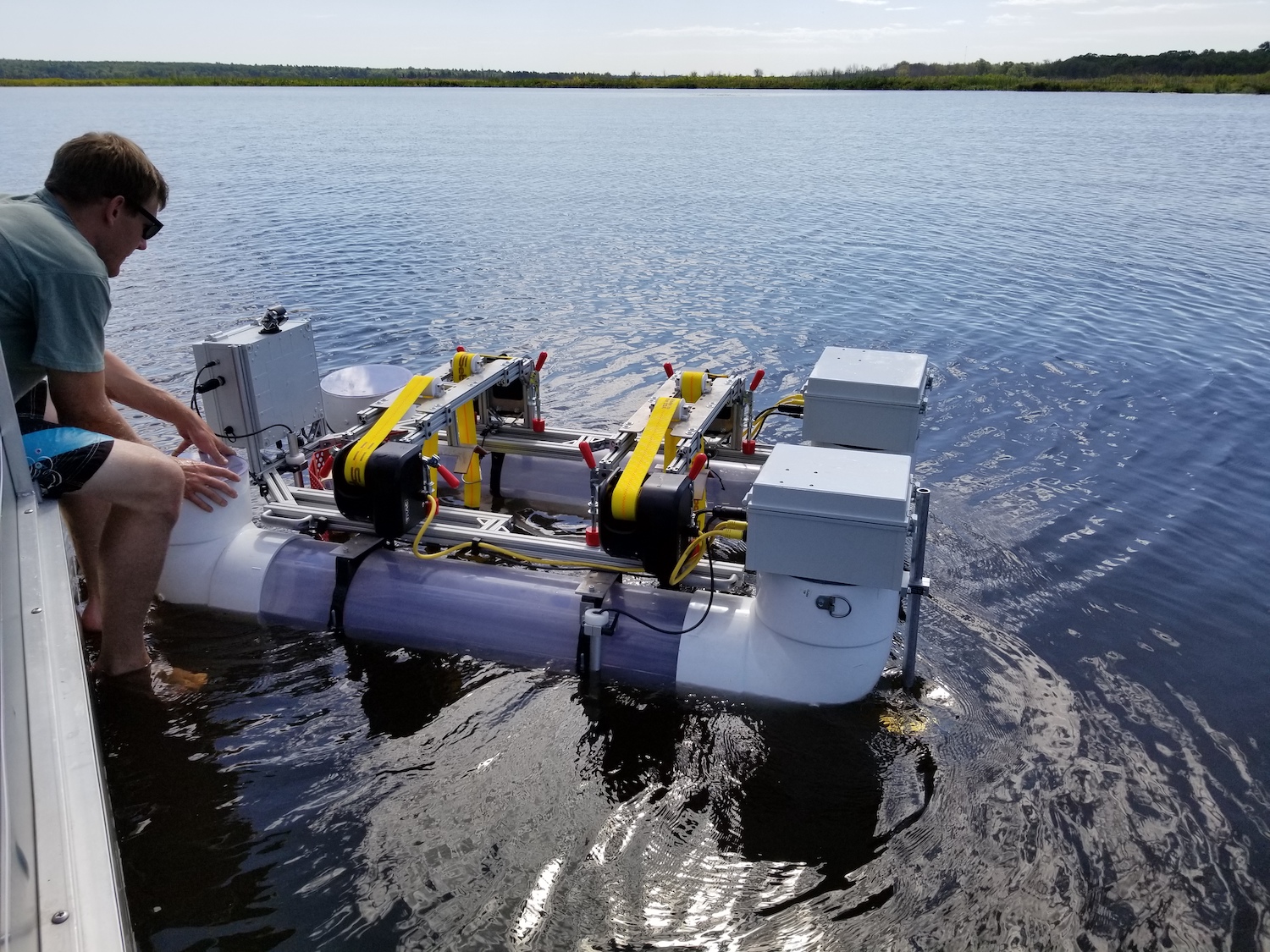

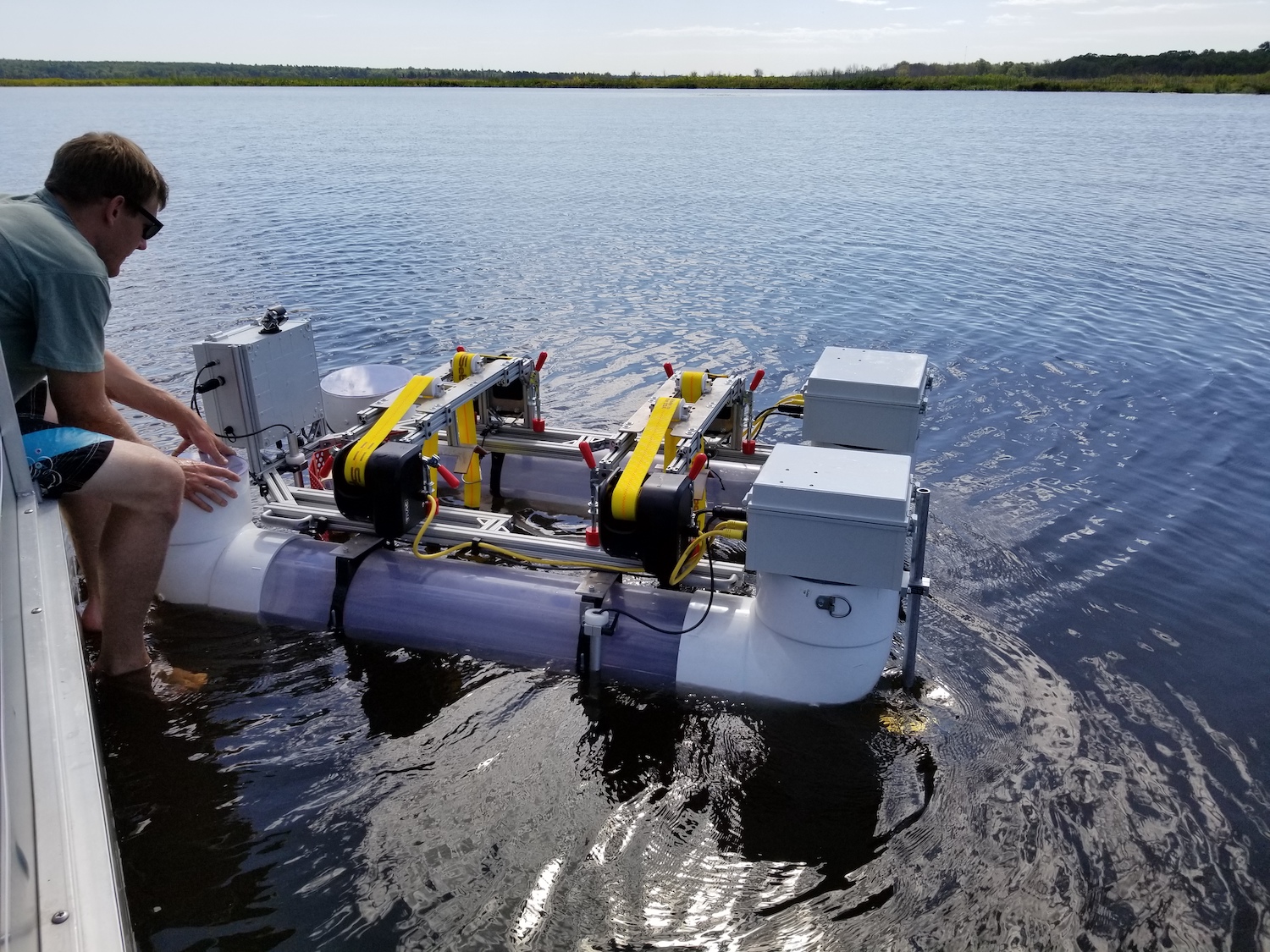

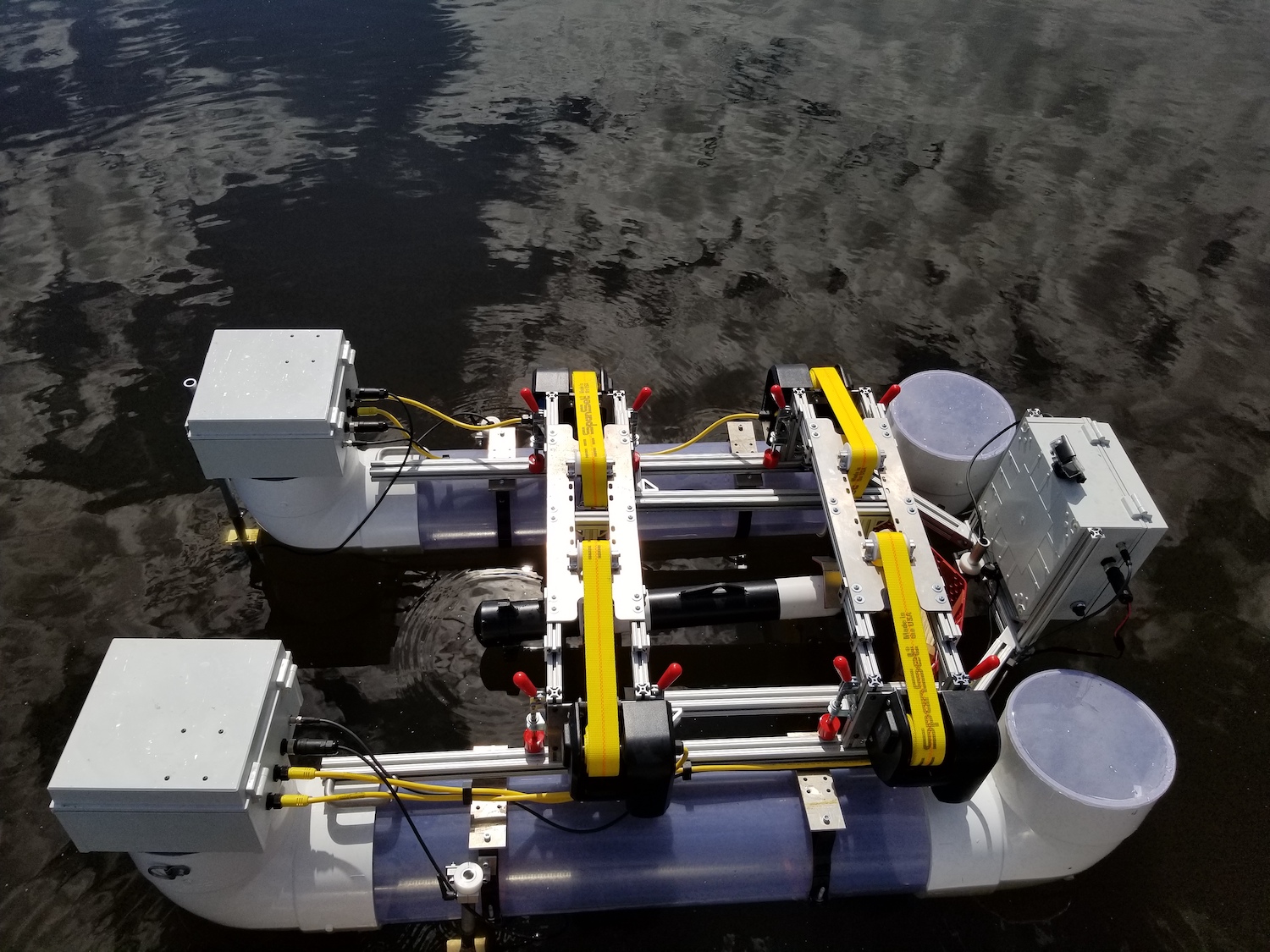

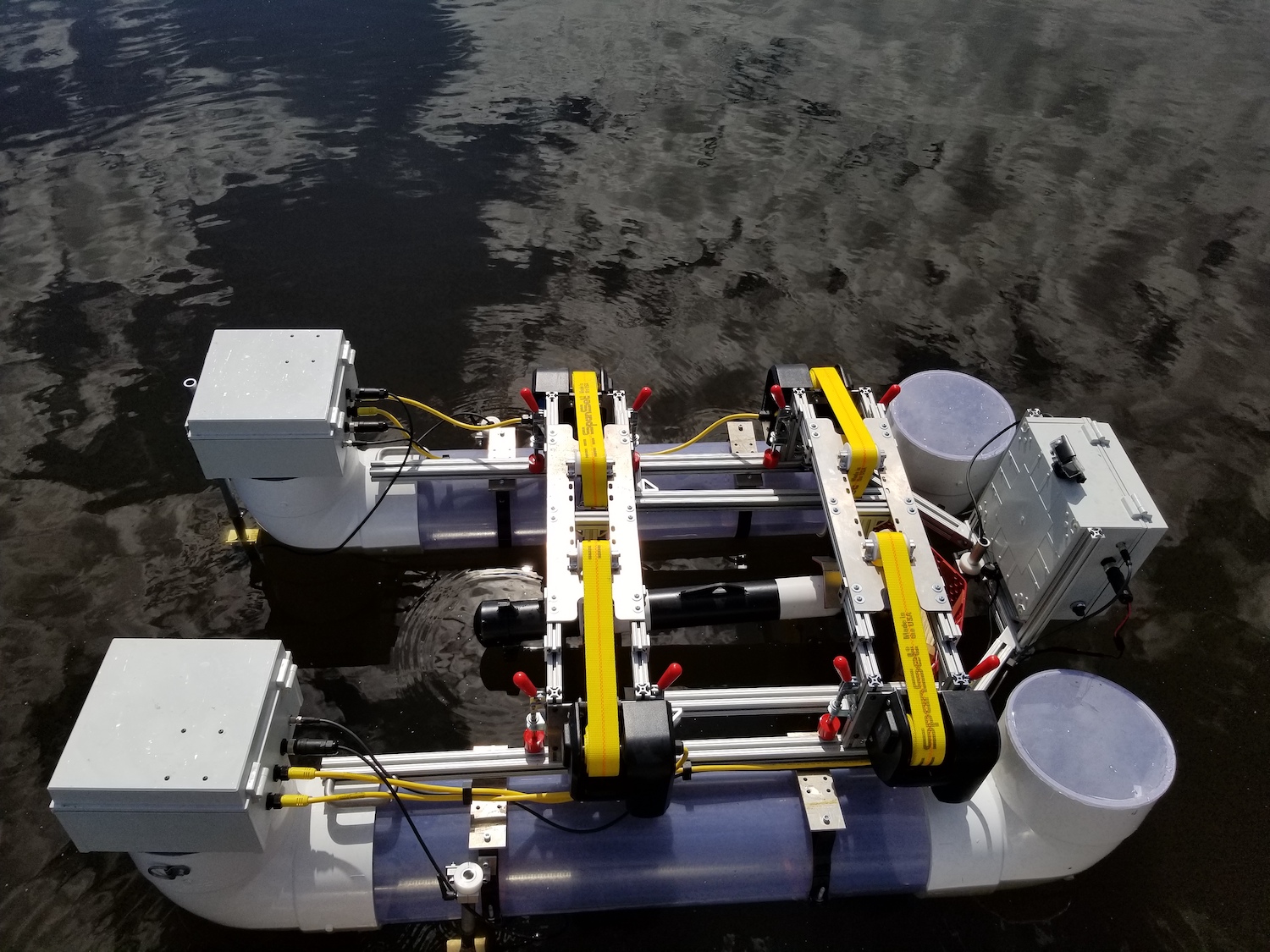

GLSV was awarded a Phase-I and Phase-II SBIR from the US Navy to develop a modular, adaptable launch & recovery system for a wide range of UUVs that will offer a common platform for both the Independence and Freedom classes of LCS ship. GLSV’s unique recovery device will utilize the stern overhead crane on both ships for deployment and recovery. The new system will provide fast-tempo L&R of UUVs during Sea State 3 conditions, and will offer a cost savings due to the common, adjustable platform. GLSV’s recovery system could also be used in numerous commercial applications such as offshore oil and gas, environmental monitoring, hydrography, and search and recovery.

US Navy SBIR to develop an improved depth control system for an Acoustic Device Countermeasure for anti-submarine warfare.

GLSV was awarded a Navy Phase-I SBIR to develop an efficient depth control mechanism capable of being implemented into existing and future 3-inch Acoustic Device Countermeasures (ADC) to allow for increased power for improved acoustic performance. These countermeasures are launched from surface ships and submarines to counter torpedo threats. GLSV developed multiple concepts which have quantified performance and efficiency improvements through dynamic modeling and simulation. GLSV has been selected to continue the development in a Phase-II effort, which is currently pending contract award.

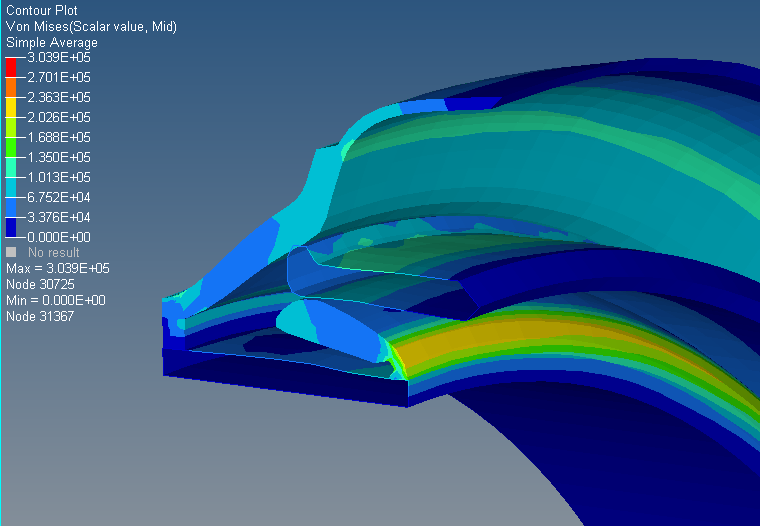

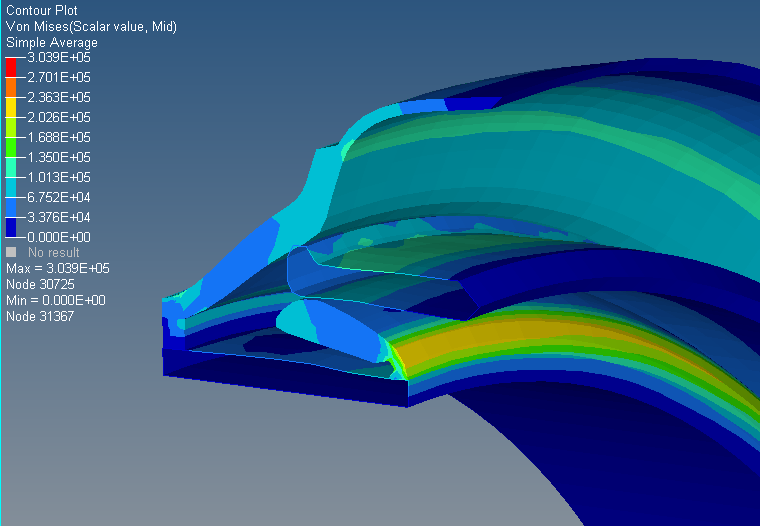

US Army SBIR for Leak Proof Intake Plenum Seal for M1 Abrams Turbine Engine

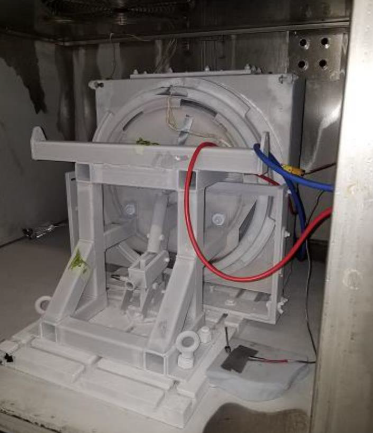

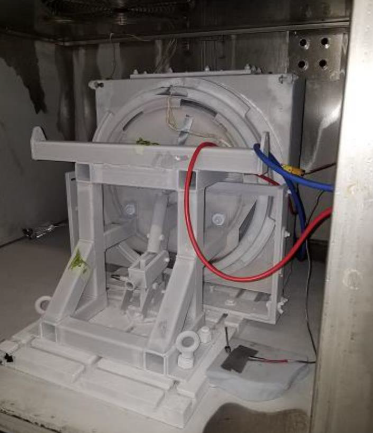

GLSV developed a new intake plenum seal for the M1 Abrams advanced gas turbine engine under contract with the U.S. Army. Currently under a Phase II SBIR Enhancement effort, GLSV is qualifying the new design for performance in a range of environmental conditions. GLSV has developed custom control hardware to run in-house test cycles, record, and analyze for all in-house environmental testing. GLSV is working with external laboratories to qualify the product in a wide range of environmental conditions per ATPD-2404 Environmental Requirements. GLSV has engaged with Honeywell, the supplier of the engine/seal, and GLSV is in line to become the sole source supplier of this engine plenum seal for the next M1 Abrams upgrade as part of the Total Integrated Engine Revitalization (TIGER) program. The image below (left) shows the newly designed intake plenum seal immediately after exposure to -60 deg F environment at GLSV’s laboratory facility.

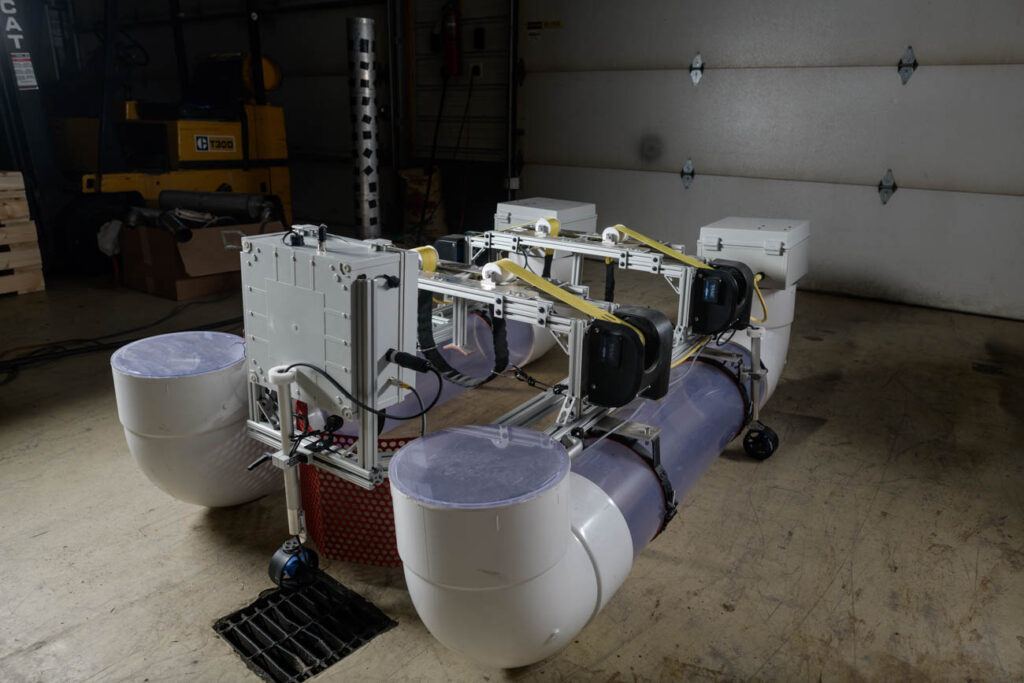

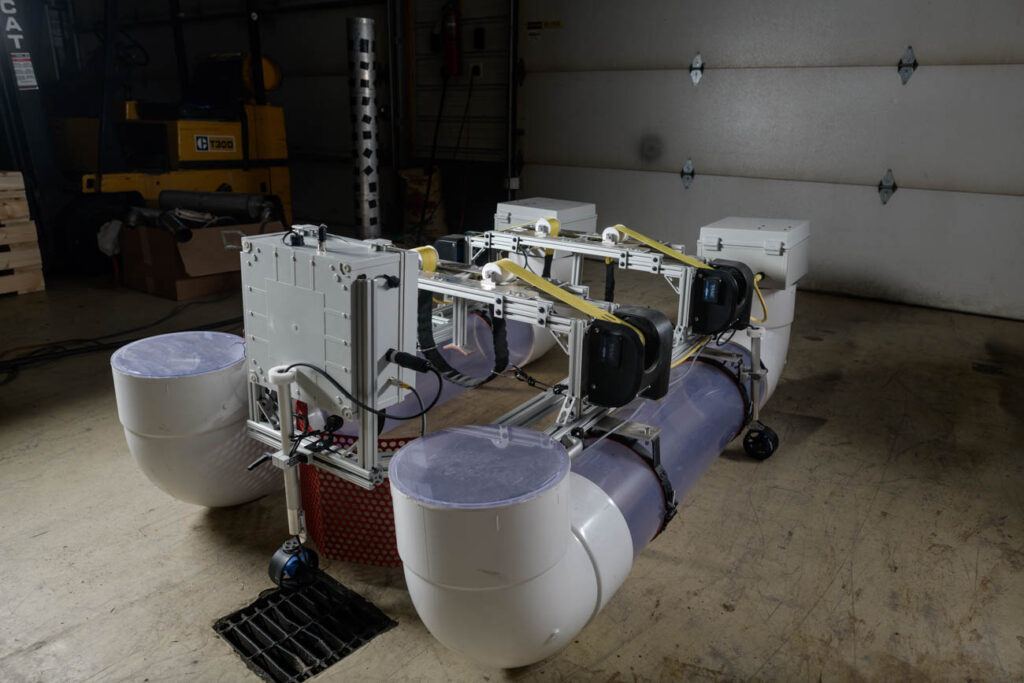

US Navy SBIR to develop a modular buoyancy kit to assist stern ramp launch & recovery of amphibious vehicles.

GLSV was awarded a Navy Phase-II SBIR to develop an innovative, modular buoyant kit (MBK) that will allow the Expeditionary Fast Transport (EPF) stern ramp to allow Splash-Off Launch and Retrieval (L&R) of US Marine Corps amphibious vehicles during Sea State-3 conditions. The MBK is designed to be deployable and would attach to the end of the EPF stern cargo ramp, and is augmented by a novel dynamic compensation system to minimize damaging ramp motions due to wave action and vehicle movement on the ramp.

US Army SBIR for Active Cancellation of Exhaust Noise in Ground Vehicles

GLSV completed a Phase II Enhancement SBIR effort to develop an active noise control technology to cancel exhaust noise on a FOSOV vehicle. This is a continuation of a previous effort to develop ANC exhaust system for an under armor APU unit. The APU system was successful in demonstrating 20 – 30 dB of tonal attenuation in exhaust noise from 40 – 400 Hz.

US OSD SBIR for Active Noise Control for Small Caliber Ammunition

GLSV completed a Phase I prime contract and has been awarded Phase-II to develop active and passive noise control of small caliber ammunition in support of the Joint Service Small Arms Program (JSSAP) at CCDC Armaments Center. Through the Phase I effort, GLSV showed feasibility of active/passive treatments on the projectile and muzzle blast noise signatures. For projectile noise, GLSV utilized analytical modeling to estimate a 48% reduction in detection range and a 200% increase in localization prediction error of a 5.56 x 45mm projectile utilizing the concepts developed by GLSV. GLSV also provided an active system concept for treating muzzle blast with an estimated noise reduction of 80 dB, which is far beyond the current state of the art of 30 dB

US Army SBIR for Active Noise Control of Fans

GLSV is currently under contract for a Phase-II SBIR with the US Army to develop an active noise cancellation system to substantially reduce tonal noise generated by fans in military ground vehicle applications. GLSV is approaching this by first characterizing fans, cancellation sources (speakers), and duct acoustic modes to understand the physical phenomenon of the fan noise generation. GLSV has collected noise data of fans and cancellation sources utilizing a custom acoustic/flow bench, constructed and validated an acoustic FE/BEM model, and developed a preliminary controller capable of substantial reduction of tonal noise at blade pass frequencies. This work is building upon GLSV’s successful development of an active exhaust noise cancellation system which was demonstrated on multiple ground vehicles. GLSV intends to continue with higher frequency noise cancellation, extending to higher complexity mode shapes, multiple harmonics, and faster control hardware.

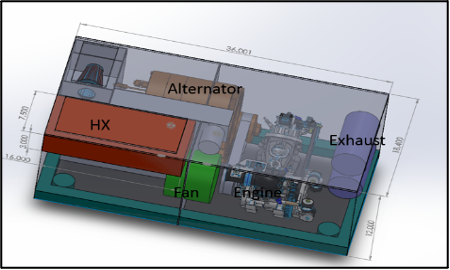

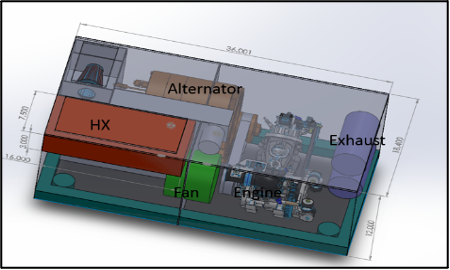

US Marine Corps SBIR for Compact APU System for Amphibious Combat Vehicle

GLSV was awarded a Phase-I SBIR to develop a new design for an auxiliary power subsystem (APU) for the Marine Corps ACV amphibious vehicle. GLSV developed and evaluated a new design layout and new technologies to be incorporated in the system. Engineering design calculations were supplemented by reduced order and 3-D simulations and modeling to assess and optimize performance for air flow, cooling performance, noise, power output, and efficiency. Simulation tools included solid modeling, computational fluid dynamics, multi-physics 1-dimensional dynamic system modeling, and boundary element acoustic modeling.

US Army SBIR for Affordable High Performance Exhaust Development

GLSV completed a Phase-II SBIR for US Army RDECOM-TARDEC (since renamed to Ground Vehicle Systems Center) to develop a modular process for the design and manufacturing of high performance ‘build to order’ passive exhaust systems. The process focuses on cost effective design and manufacturing for low to mid production quantities. GLSV developed software to interface between manufacturing-level CAD models and 1-dimensional acoustic/flow models to produce an optimal environment for designing custom exhaust systems for a wide variety of applications. GLSV also developed novel processes for design and manufacturing of exhaust systems to ensure modularity and adaptability while maintaining flexibility to optimize performance and durability.

Recon and Surveillance Vehicle Demonstrator

GLSV was contracted by a large defense prime to manufacture a functional vehicle demonstrator under the previous Army Future Combat Systems program. The demonstrator was required to be representative of the characteristic mass, power, size and shape of a production vehicle, in order to accurately represent the thermal signature characteristics of the actual vehicle. This was a complete turnkey effort encompassing design and build from the ground up, with a completely custom hydraulic propulsion system and custom drive-by-wire operator controls.

GLSV fabricated and built a complete aluminum body and frame, and integrated the track, engine, and drivetrain components (including all controls). The body and frame manufacturing activities encompassed water jet cutting, sheet metal forming, machining, and welding.

GLSV explores and develops cutting edge technologies and products

News from GLSV

GLSV supplying diesel exhaust silencers for the Offshore Patrol Cutter.

Offshore Patrol Cutter (uscg.mil) GLSV has been awarded a contract to supply diesel exhaust silencers for the OPC (Offshore

GLSV expands manufacturing capabilities with laser table and seam welder.

SPACE GEAR MARK 510 II Great Lakes Sound and Vibration has invested in laser cutting for flat and multi

GLSV awarded contracts to supply shock absorbers to DLA for multiple ground vehicle platforms.

Shock absorber on test stand at GLSV South Location. Photo by Christian Muehlfeld Great Lakes Sound and Vibration has